What’s so special about fabric backlit signs?

Have you noticed? Fabric-faced lightboxes are everywhere! Clearly, there’s a movement toward fabric as the medium of choice for commercial-grade backlit signs in every context from retail product promotion to institutional fine art display. Let’s take a look at the reasons discerning marketers and interior planners are turning to fabric for their LED backlit sign solutions:

THAT ORGANIC LOOK — Only lightboxes with a backlit fabric graphic can give you a zero-glare graphic surface and still deliver a bright, saturated color image. This is why you’ll find backlit fabric signage in TV studios, corporate lobbies, fashion and cosmetic retailers — any place where a softer, more humanic presentation may be desired without compromising color bandwidth.

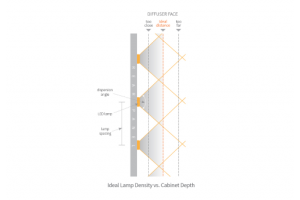

LIGHT WEIGHT — Not many people realize that the heaviest components in a conventional backlit sign are the two acrylic or polycarbonate lenses between which the duratrans backlit film is sandwiched and held in place. But not so with a fabric backlit sign, because the fabric graphic face is held flat via stretch tension from edge to edge, so no lenses are needed. This is only possible because of the tensile properties of fabric, as contrasted with the much more dimensionally-stable polyester film used for conventional backlit graphics. This can result in a weight savings near 50% in some cases, and it’s one reason backlit fabric signs are popular with trade shows, traveling exhibits and environments where handling and/or installing heavy, cumbersome display fixtures is at best inconvenient or at worst unsafe.

SECURE TRANSPORT — This is not the first thing that comes to mind for most people planning a backlit sign installation, but it may be the most practical, on three different levels: First, as mentioned above, your shipping weight with fabric lightboxes is always going to be significantly less than that of a conventional lightbox sign, due to the absence of plastic lenses as previously noted. Second, most fabric lightboxes can be shipped disassembled with the backlit fabric folded or rolled in the carton, so now the dimensions of your shipping container are a fraction of what they would have been for an aluminum backlit sign of the same display size. Lastly and most often overlooked is the relative damage resistance of a fabric lightbox — no heavy, flat, brittle lenses with sharp corners to secure!

PRICE PER SQUARE FOOT — And now for everybody’s favorite reason to opt for fabric backlit signs: the savings that can be realized. This is especially true for large or jumbo backlit signs, from 4 or 5 feet in one dimension all the way up to 10 feet or even 15 or 20 feet. As you can imagine, the incremental price to add a few square feet of mostly just a digitally-printed backlit fabric (since there are no “lenses”) is nominal compared to all the additions of metal parts and high-technology plastics required to achieve the same size in a conventional backlit sign.

Next time you’re in a public or commercial space such as an airport, shopping mall, casino, sports arena or any interior venue where large backlit messaging is found, take a close-up look and you’ll be surprised to find more and more tension fabric lightboxes such as Blue River Digital’s FabricLyte Econo LED with LyteStretch backlit fabric, which from more than a couple feet away, appears to have all the saturation, boldness and detail of any legacy backlit sign you’ve seen before.